The ‘dead man’s switch’, or ‘dead man’s pedal’ is a standard safety feature on many forklifts, but it hasn’t seen much innovation over the years.

These switches appear on lots of different vehicles and machines, and are designed to stop the machine from operating if the driver isn’t in full control. In the case of a forklift, the dead man’s switch must be held down (usually with the foot) in order for the truck to operate. This makes sure that if the driver becomes incapacitated, isn’t in control of the truck, or even isn’t in it at all, it won’t be able to move.

It’s a smart and simple solution that has prevented countless accidents. But on trucks where the operator is standing, like some order pickers, it’s far from the perfect solution and can even introduce some new safety issues itself. Here’s why:

It’s a tripping hazard

On order picking trucks, the switch is usually a pedal in the floor of the cabin. Naturally, it protrudes above the level of the floor slightly. It is common practice for operators to walk through the cabin while order picking rather than walking around the truck, this means stepping on or over the dead man switch. If you’re looking to reduce accidents and injuries in your warehouse, you should be removing all tripping hazards - but how do you remove the ones built in to your trucks?

It can limit driver movement

By design, the driver needs to keep the switch pressed down when driving the truck. But this can quickly become an annoying restraint during the course of a shift, requiring the operator to always stand in exactly the same position on the truck after each and every pick. Operators need to be able to find a safe driving position that is comfortable to them over an entire shift, regardless of their individual leg or arm length or overall height. A small fixed pedal in the floor isn’t the best way to ensure this.

It can cause strain

You only need to stand on the dead man’s pedal to apply it - no force is required to push it down. However, it is natural that operators will often shift their weight onto the foot holding down the pedal without even realising it. Over the course of a long shift, this can cause strain in the leg and foot - which slows things down, can causes discomfort and even injury to the driver.

It’s another thing which can break

Even if all efforts are made to shield the opening around the pedal from dust or water, there’s still an opening there. Busy order picking operations will often result in some level of debris from shrink wrapping, damaged pallets, etc. Over time, debris can and does get in around the pedal, causing it to malfunction - and if the switch doesn’t work, the truck isn’t going anywhere!

It can be abused

The dead man’s switch is just a simple on/off button. It can only tell if it’s being pushed down, not who or what is pushing it down. This means that operators can potentially place an object onto the pedal or even tape it down to override it if they don’t like using it. This obviously causes a number of major safety issues.

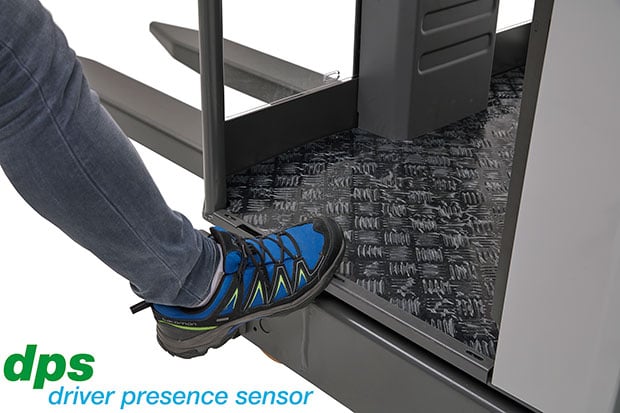

The dead man’s switch has become the industry-wide standard solution, but it has its issues. However, there is a better, different way. By swapping the switch for a floor sensor, which covers the floor of the order picker and detects the operator’s presence wherever they are standing, many of these problems disappear.

For example, there’s no switch to trip on, since the sensor is under the cabin floor. The driver’s movement isn’t limited, because the sensor can tell he’s there regardless of where or how he stands in the truck. There’s no strain, since only a natural standing position is required for the sensor to work. No floor openings mean nowhere for debris to enter the truck, and it’s much more difficult to trick than a small switch.

This innovation from UniCarriers makes a big difference for order pickers, where safety and ergonomic benefits can really make a difference to the bottom line. To see how it works in practice, take a look at the EPM or EPH order pickers - the Driver Presence Sensor (DPS), our floor sensor solution, was nominated for the International Forklift of the Year (IFOY) award in 2017.

If you’re curious about how this solution and others like it could benefit your material handling operation, click the button below to get in touch. We’ll be happy to tell you about the benefits.

Comment