Warehouse automation is a hot topic in the materials handling industry at the moment. Stories about companies like Amazon's financial successes are often accompanied by videos showing swarms of robots shuttling goods to human workers who carry out fewer and fewer manual tasks.

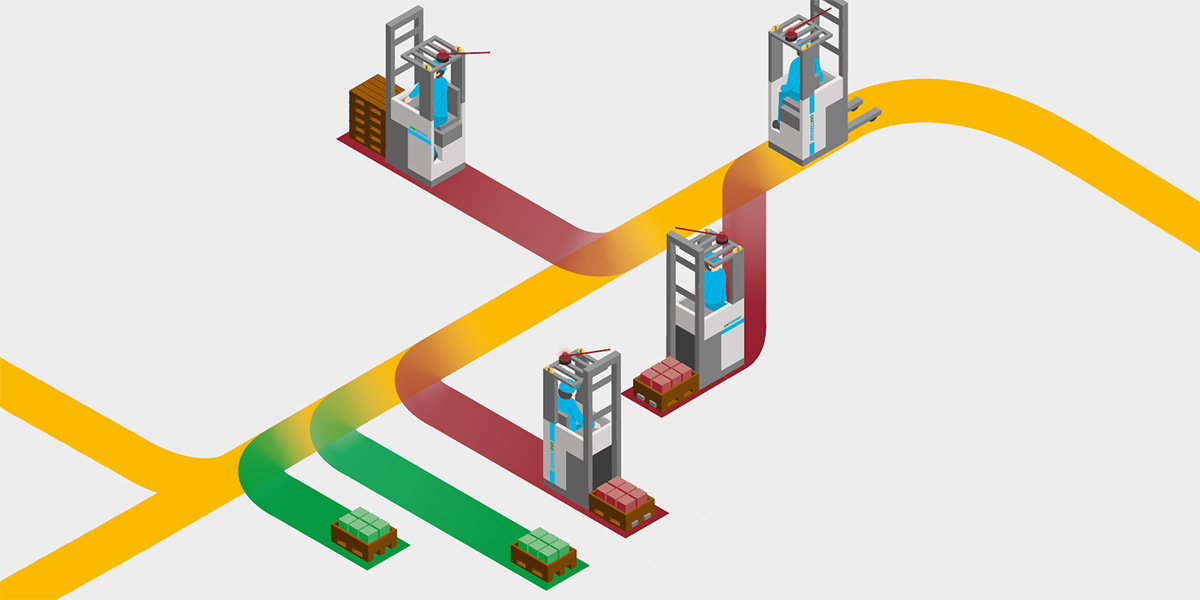

However, introducing automation to a materials handling operation doesn't necessarily mean getting rid of staff entirely. Instead, fully or partly-automated equipment and human workers can work together, with automation focusing on improving efficiency, safety and sometimes eliminating the need for humans to carry out the most repetitive tasks.

Comment