Warehouse automation is a hot topic in the materials handling industry at the moment. Stories about companies like Amazon's financial successes are often accompanied by videos showing swarms of robots shuttling goods to human workers who carry out fewer and fewer manual tasks.

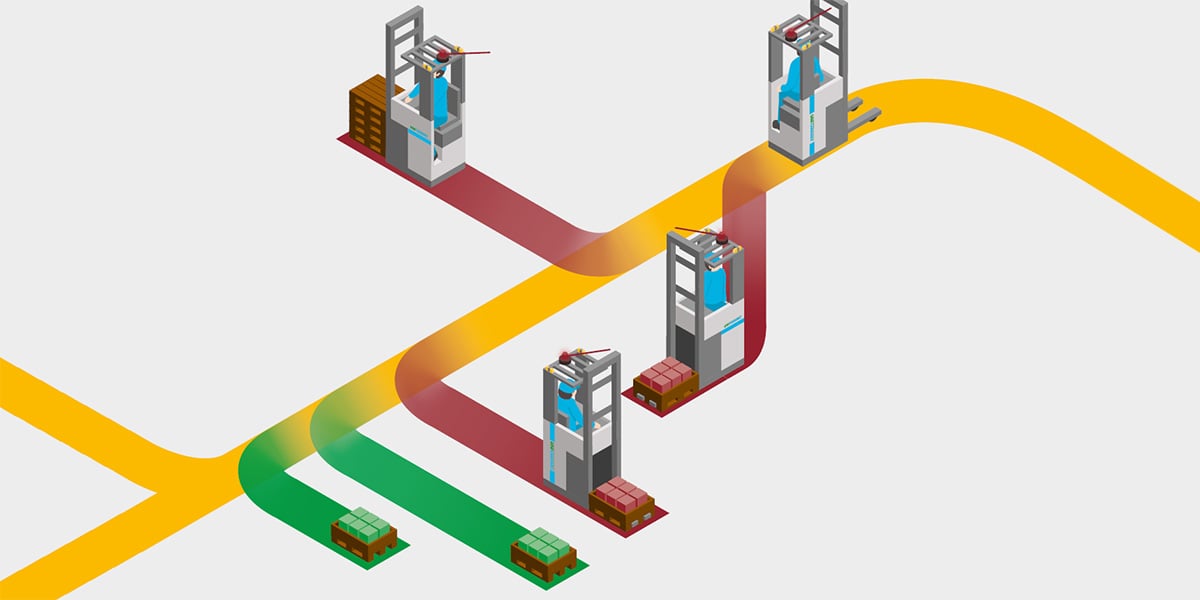

However, introducing automation to a materials handling operation doesn't necessarily mean getting rid of staff entirely. Instead, fully or partly-automated equipment and human workers can work together, with automation focusing on improving efficiency, safety and sometimes eliminating the need for humans to carry out the most repetitive tasks.

Automated guided vehicles (AGVs) and other automation solutions aren't as new as many people think - they've been working in warehouses for decades. However, more recent advances in technology mean that automation has become more reliable, flexible and affordable than ever before.

Introducing automation to your warehouse doesn't have to mean scrapping your whole operation and buying a fleet of robots. In fact, there's a number of different levels of automation that could benefit all kinds of business. If you want to find out more about the possibilities available to you, you can read our free guide, How can you automate your materials handling operation? In the guide, you'll learn more about:

- The unexpected safety issues that must be addressed before AGVs are introduced

- How a 'best of both worlds' solution can work for operations that aren't suited to full automation

- The different kinds of guiding systems that driverless forklifts can use to get around the warehouse

If it sounds interesting, click the button below. After filling in the short form on the next page, the free guide will be yours to keep.

Comment