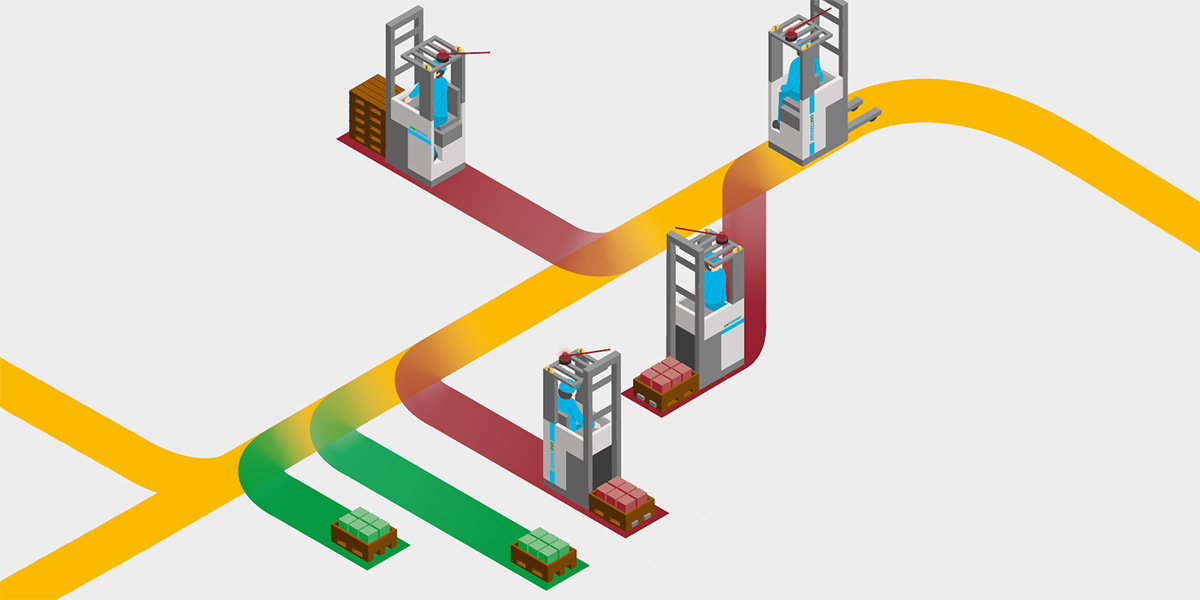

Automated guided vehicle (AGV) technology has been used in materials handling for decades, but with more recent developments in technology it's becoming a more affordable and flexible solution than it used to be.

Paul Boynton

Latest articles

Warehouse automation: How to get the best of both worlds with AGVs

Automating a material's handling operation: what are your options?

Warehouse automation is a hot topic in the materials handling industry at the moment. Stories about companies like Amazon's financial successes are often accompanied by videos showing swarms of robots shuttling goods to human workers who carry out fewer and fewer manual tasks.

What is warehouse turnover?

The wide world of materials handling-specific terms can be difficult at the best of times, especially for someone who may be new to or not so familiar with the industry. One of the more misleading terms is turnover – for most people, a fairly common word which refers to the amount of money taken in by a business during a certain period.

Forklift service: How to reduce your operation's carbon footprint

There's many ways that the carbon footprint of a materials handling operation can be reduced. Using electric trucks instead of IC trucks brings down emissions, for example, and energy can be saved by choosing more eco-friendly heating and lighting systems.

However, if you want to reduce the carbon footprint of your company's forklift service operation, then choosing a service partner with a high first visit fix rate (FVFR) is a great solution.

What is logistics simulation?

"The representation of the behaviour or characteristics of one system through the use of another system, especially a computer program designed for the purpose."

Planning a warehouse, or thinking of making changes: How to use simulation software to help

When planning a new warehouse, or thinking about making changes to an existing one, it's possible to use some basic figures about the operation to make an analysis of how effective the solution will be.

Guide: The benefits of logistics simulation

Building a solid and efficient materials handling operation doesn't start with buying a truck — instead, the process should always begin with a careful analysis of your needs and current operation, so you can see what is being done right, and what needs to change.

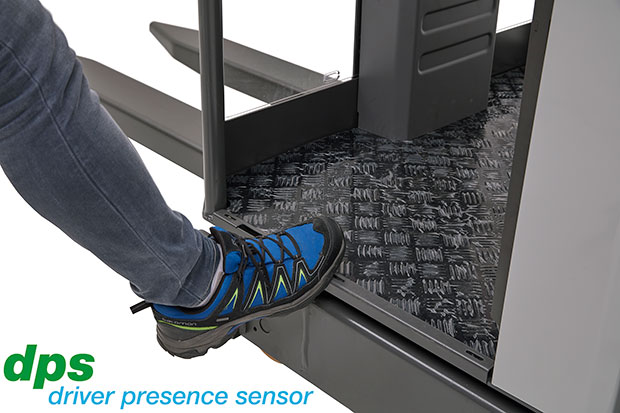

The 'dead man's switch' - is it really the best solution for order pickers?

The ‘dead man’s switch’, or ‘dead man’s pedal’ is a standard safety feature on many forklifts, but it hasn’t seen much innovation over the years.

These switches appear on lots of different vehicles and machines, and are designed to stop the machine from operating if the driver isn’t in full control. In the case of a forklift, the dead man’s switch must be held down (usually with the foot) in order for the truck to operate. This makes sure that if the driver becomes incapacitated, isn’t in control of the truck, or even isn’t in it at all, it won’t be able to move.

It’s a smart and simple solution that has prevented countless accidents. But on trucks where the operator is standing, like some order pickers, it’s far from the perfect solution and can even introduce some new safety issues itself. Here’s why: