Shuttle racking certainly isn't the cheapest storage system available, but if you want to maximise the capacity of a warehouse, it's a fantastic option.

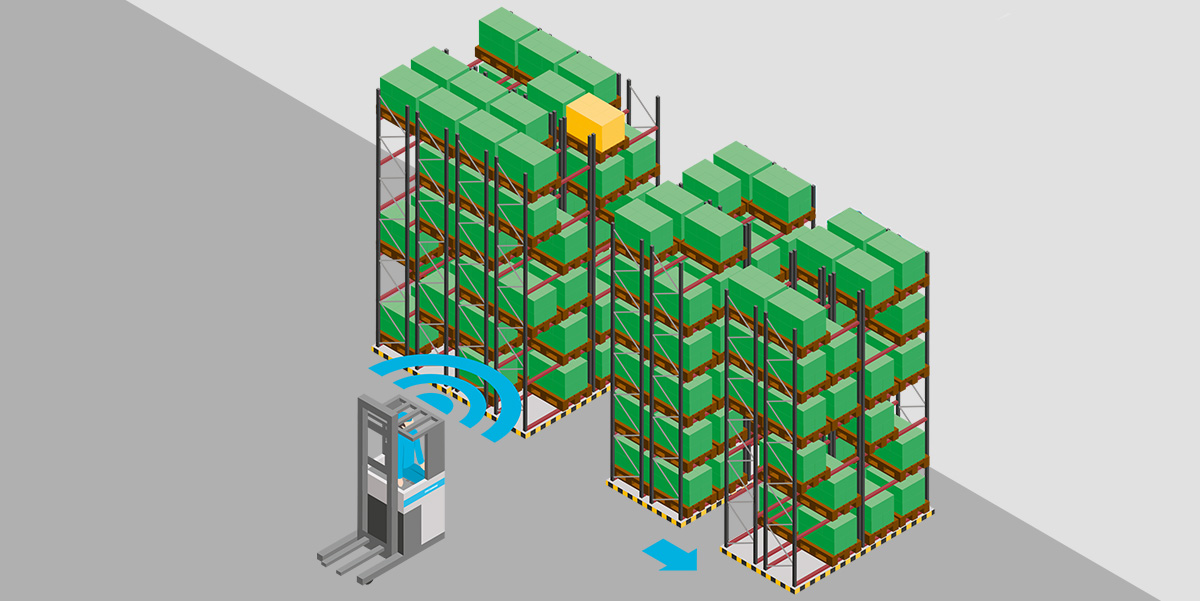

What is shuttle racking, and how is it used in materials handling?

What is warehouse turnover?

The wide world of materials handling-specific terms can be difficult at the best of times, especially for someone who may be new to or not so familiar with the industry. One of the more misleading terms is turnover – for most people, a fairly common word which refers to the amount of money taken in by a business during a certain period.

What is logistics simulation?

"The representation of the behaviour or characteristics of one system through the use of another system, especially a computer program designed for the purpose."

The benefits and drawbacks of mobile racking

When it comes to making efficient use of space in your warehouse, mobile racking is one of the leading options. With this storage system, the racking itself stands on motor-driven wheels which move in rails built into the floor.

Warehouse planning: How it worked for Britvic

When planning a new warehouse, there's a huge amount of different factors that have to be considered - the type of items being stored, the available floor space and height in the building itself, and the correct storage system that will both maximise the use of the space available but also make it easy to access pallets.

Brexit: How to overcome your current stockpiling challenges

For the last few months, the papers have been filled with stories about the storage issues that companies across the country are facing. A shortage of storage space is becoming more and more of an issue for all kinds of businesses, as companies begin to stockpile goods due to fears of Brexit-related disruption. Warehousing and capacity is therefore a major challenge.

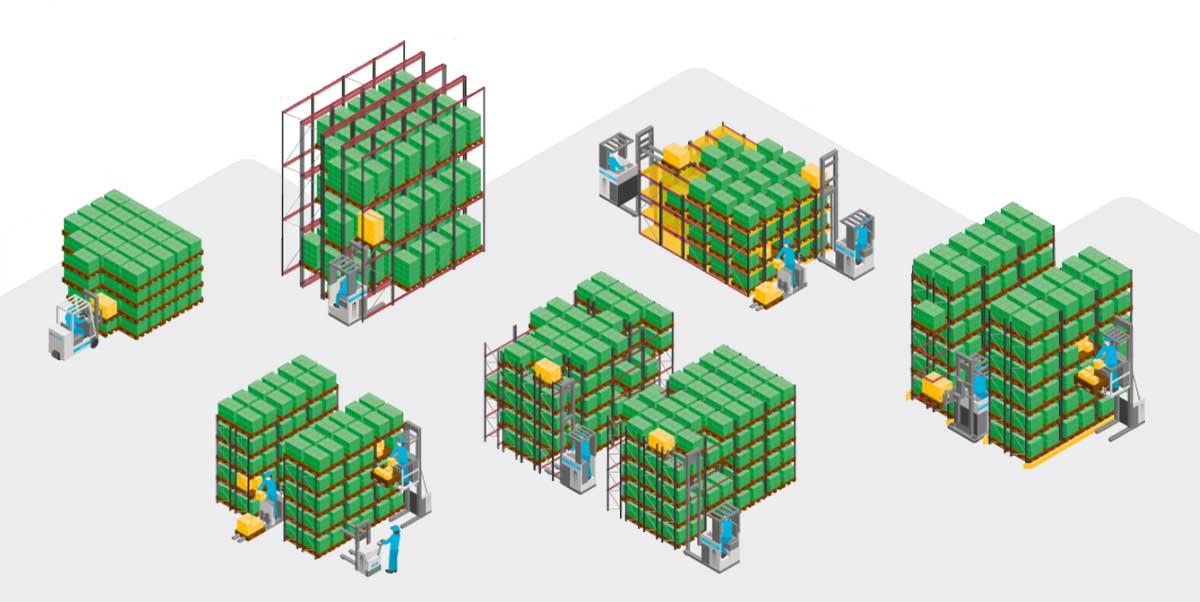

Dense warehouse storage systems: Which one is best for you?

Making the most efficient use of the available floor space in your warehouse is always important. However, when the density of storage increases, placing and removing unit loads when you need to, typically takes more time.

Cold store: What is the best choice of storage system?

Cold stores are some of the most challenging environments that forklifts can operate in — temperatures as cold as -35°C are not unusual in these facilities, which are an absolutely vital part of the modern supply chain.