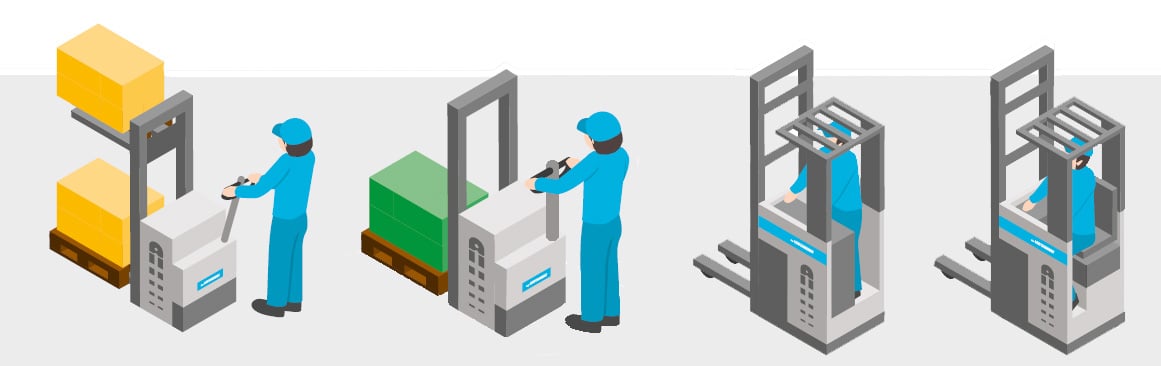

An operation like loading and unloading goods can be made much more efficient in various ways, like by using loading bays, or stand-on pallet trucks instead of pedestrian versions. Order picking, a repetive and expensive logistics process, offers even more possibilities for optimisation. But for the third main part of materials handling - the intake and retrieval of entire unit loads within the warehouse - what can you do increase efficiency and productivity?

As always, it depends on the operation. There are as many possible solutions as there are operations and looking carefully at yours will help you find the right machine. The size of the warehouse, for example, is a major factor. Are cycles very long due to long distances being travelled? If so, greater ergonomics and more comfort could be necessary. Choosing a sit-on over a stand-on stacker could help here.

Paying attention to these details can save you money, too. Do you really need a full-size reach truck, when a cheaper, less powerful truck would be enough for your needs? For narrow-aisle operations, would man-up or man-down be the best option?

In this vital part of the handling process, big efficiency and monetary gains can be made - so if you're planning for new truck purchases in the future, getting a clear picture of what you need is vital. To help with this, click the button below to get the guide Choosing the right truck for the job.

It will give you a comprehensive overview of the different types of forklift usually used for the intake and retrieval of unit loads, and what situations each truck performs best in. It also includes sections about trucks for loading and unloading, and order picking trucks — so if other parts of your operation need improvement, it can help there as well. Click the button to get started.

Comment