When planning a new warehouse, there's a huge amount of different factors that have to be considered - the type of items being stored, the available floor space and height in the building itself, and the correct storage system that will both maximise the use of the space available but also make it easy to access pallets.

Latest articles

Warehouse flooring: What standard do you need?

The warehouse floor certainly isn't the most exciting part of a materials handling operation, but it's the part on which everything else is built — and flooring-related problems can be a big safety hazard.

Forklift leasing: How it can give you access to the latest technology

With proper service and maintenance, a high-quality forklift truck can put in years of service, even in a busy materials handling operation. And depending on the unique requirements of your operation, an older used machine could potentially do the job just as well as a brand new truck.

Soft costs: What they are, and why you should focus on them

When the time to purchase new forklifts comes, the focus is always on costs. This makes sense — no-one in business would want to spend money unnecessarily, and if a machine can do the job, then the lower the cost, the better.

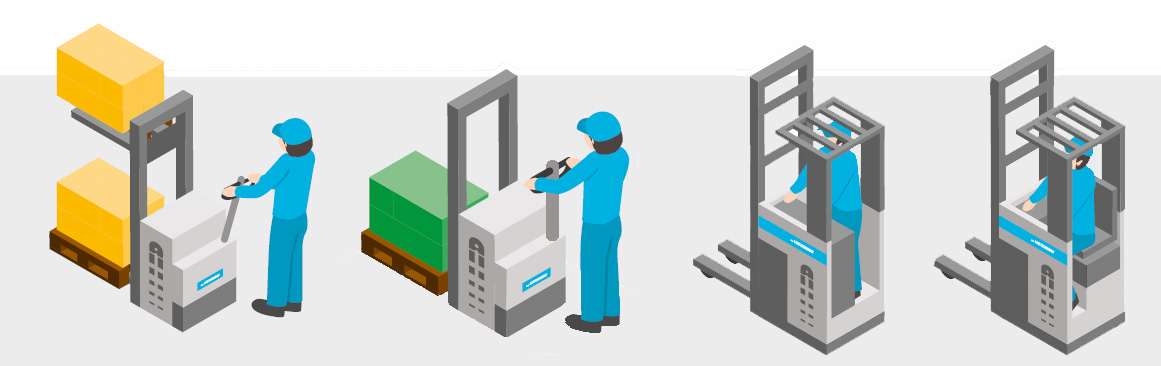

Trucks for placing and removing pallets: Which is best for your warehouse?

An operation like loading and unloading goods can be made much more efficient in various ways, like by using loading bays, or stand-on pallet trucks instead of pedestrian versions. Order picking, a repetive and expensive logistics process, offers even more possibilities for optimisation. But for the third main part of materials handling - the intake and retrieval of entire unit loads within the warehouse - what can you do increase efficiency and productivity?

Order picking and the human body: How to reduce injuries and strain

Everyone could easily lift a package weighing a few kilograms, but what if you had to pick that same package hundreds of times a day, over the course of weeks and months, possibly from hard-to-reach places? You’d probably start feeling the strain quite quickly, and you’d end up hoping you had some equipment or solution to make the job easier.

How much difference can a forklift's steering wheel make?

The forklift’s steering wheel is a component that is often taken for granted, but it’s usually the most-used. Navigating a busy warehouse requires a lot of manoeuvring, and the driver has to make constant adjustments in order to drive safely.

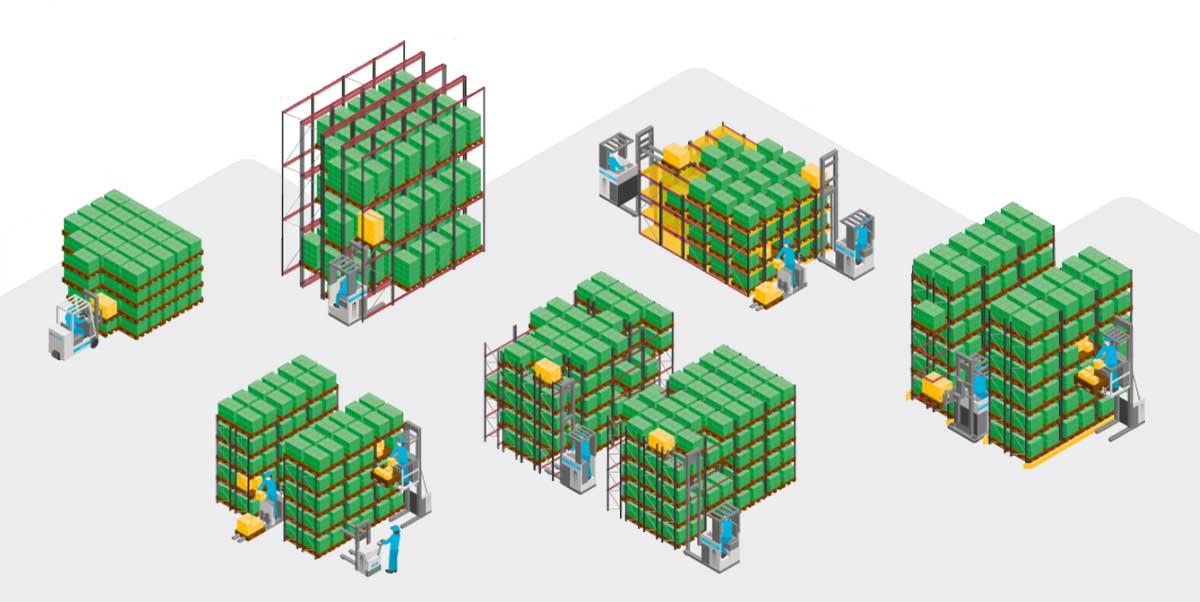

Dense warehouse storage systems: Which one is best for you?

Making the most efficient use of the available floor space in your warehouse is always important. However, when the density of storage increases, placing and removing unit loads when you need to, typically takes more time.

Four things that can harm forklift drivers — and how to prevent them

Operating a forklift is a demanding job, and the stresses of a busy materials handling operation can put strain on drivers. This doesn't only make them uncomfortable and prone to injury, but also makes them less efficient and productive, harming the operation's bottom line.

Cold store: What is the best choice of storage system?

Cold stores are some of the most challenging environments that forklifts can operate in — temperatures as cold as -35°C are not unusual in these facilities, which are an absolutely vital part of the modern supply chain.