The traditional lead-acid forklift battery is a tried-and-tested technology that is still being improved, and it's still the most common source of power for electric forklifts. However, there's still not a solution for the regular maintenance these batteries require to keep working at their best.

How can you save time on forklift battery maintenance

How warehouse ergonomics and safety can boost your bottom line

Keeping warehouse staff happy, satisfied and motivated is a challenge which warehouse managers face every day. A big part of this challenge is safety - protecting staff from injury is one of the most basic requirements, and the industry has improved greatly in this area in the last few decades.

Getting the right equipment, staff and suppliers can help you achieve your goals, but there's one factor which is just as important - ergonomics.

The material handling trends of the last few decades have helped keep safety high and workplace accidents low, reducing downtime and increasing productivity. But protecting drivers from strain, repetitive movements and unnatural driving positions through forklift truck ergonomics can give similar rewards.

If you want to find out:

- How an ergonomic forklift can improve driver health and warehouse efficiency

- What the experts say about ergonomic design in the material handling industry

- Where essential controls should be positioned for maximum comfort

Then you should click the button below to download the full article. Happy driving!

Not just trucks: How an all-round solution can boost your business

Creating an effective materials handling operation is hard, and it's even harder if you have to deal with different suppliers for your forklift trucks, fleet management solution, service and rental. Even with smaller fleets, juggling different suppliers can be tricky, and it means you have less time to deal with the most important thing — your operation.

Forklift service: How to reduce your operation's carbon footprint

There's many ways that the carbon footprint of a materials handling operation can be reduced. Using electric trucks instead of IC trucks brings down emissions, for example, and energy can be saved by choosing more eco-friendly heating and lighting systems.

However, if you want to reduce the carbon footprint of your company's forklift service operation, then choosing a service partner with a high first visit fix rate (FVFR) is a great solution.

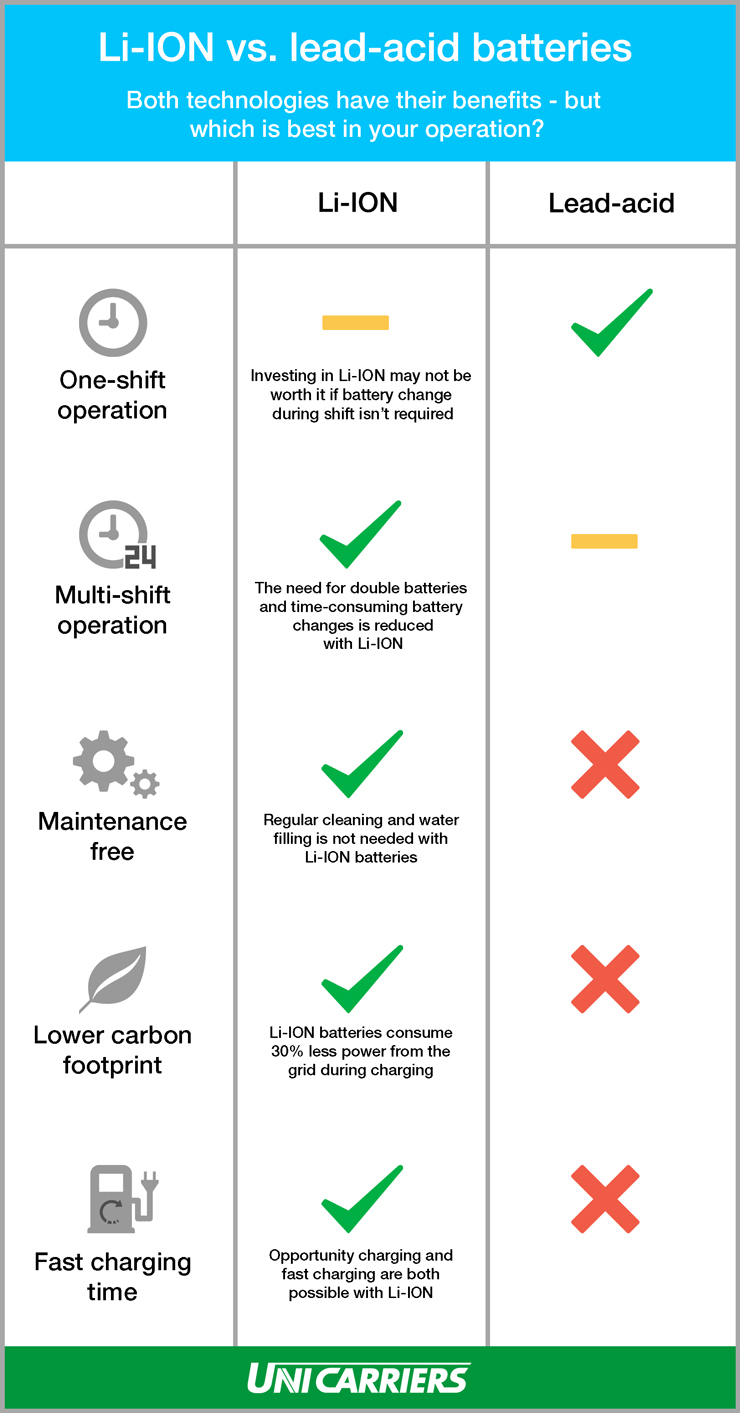

Infographic: Li-ION vs. lead-acid forklift batteries - which is best for your operation?

The traditional lead-acid forklift battery is a tried-and-tested technology. However, Li-ION (lithium ion) batteries, which power your laptop, smartphone and maybe even your car, are now a viable energy solution for forklifts. But what advantages does this new technology offer?

How many of these does your service partner offer?

You can have a fleet of the most technologically-advanced trucks on the market, but if you don't have a decent service partner to rely on, your operation will really suffer.

How your truck's step-in height affects your operation

If the surface you step onto, to get into your forklift is well-designed, you probably won't even notice it at all. But a lack of care from the manufacturer when it comes to this small detail adds to the strain that drivers experience on the job, which will ultimately affect your operation and increase costs.

Case study: How to grow a logistics operation

Picking, packing and dispatching 3,500 customer orders every day in a 118,000m2 distribution centre is a constant challenge. However, Skechers makes it happen at their facility near Liège, Belgium, with a fleet of UniCarriers trucks to help.

Condensation: A cold store truck's worst enemy

Cold stores, warehouses where frozen goods are stored, can reach temperatures as low as -35°C and are some of the most demanding environments that forklifts can operate in.

Fortunately, most forklift suppliers offer machines that are capable of working reliably in such cold temperatures. Freezing environments can make steel more brittle, make the oil and lubricants more viscous and reduce the truck's battery capacity, but adaptations can be made to forklifts to reduce the impact of these issues, ensuring both safety and reliability.

What happens when the goods you handle don't fit on standard pallets?

Since the advent of containerisation and the forklift truck, the pallet has become vital for the storage and transport of goods around the world. Palletising goods make a lot of sense - pallets are a consistent size, meaning businesses can be sure they will fit in their racking, and ensuring that all kinds of forklifts will be able to pick them up.

Pallets are also lightweight and strong in comparison to other storage and handling solutions. Pallets are everywhere, but what happens if the goods you handle are much, much bigger than the standard Europallet?