For many of the most demanding warehouse applications, a stand-in stacker can be a fantastic choice, especially in narrower aisles. In fact, if you want to improve stacking efficiency and safety, there’s no better forklift truck than a stand-in stacker - and no, even though UniCarriers pioneered the stand-in stacker in 1961, we’re not biased!

Many other kinds of trucks can stack pallets just like a stand-in stacker, and if their purchase price is lower, they may seem like more attractive machines. But the stand-in stacker’s creative design offers some major benefits.

Ergonomics

In terms of ergonomics, the stand-in stacker leads the way when compared to other models. During operation, the driver can easily adopt a natural position in the way they stand, and where they place their arms to operate the controls. Compare this to a pedestrian stacker with a platform, where the operator sometimes has to stand with locked legs for extended periods and elevate their arms to operate the tiller. Ergonomic design means less time lost to strain and discomfort, letting you get the job done quicker and easier.

Increased safety

If you want safe operation and peace of mind, a stand-in stacker is a great choice. Firstly, the driver is always inside the truck’s perimeter during operation and isn’t as exposed as they would be on a conventional pedestrian stacker. The overhead guard is often a core feature on stand-in stackers, rather than an optional extra, and along with its pillars, it protects the driver both from falling objects and side impacts. Furthermore, pedestrian stackers usually don’t have the ‘dead man’s switch’ found on the floor of many stand-in stackers, which boosts safety by preventing the truck from being operated when the driver isn’t in control.

Speed and durability

The design of the stand-in stacker typically makes it more durable than pedestrian stackers, and more resilient to occasional bumps and scrapes. These types of truck usually also have higher speeds and quicker acceleration - which means that many more jobs can be done over the course of a shift.

Space-saving design boosts efficiency

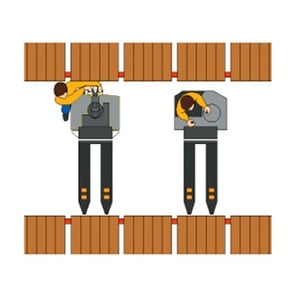

An important benefit of stand-in stackers becomes clear when you have to retrieve a pallet from a rack in a narrower aisle. With a pedestrian stacker, the aisle may not be wide enough for the driver to stand behind the truck as usual. Sometimes, they will have to stand to the side, carefully manoeuvring the truck from an awkward position to line it up with the pallet.

With a pedestrian stacker, the aisle may not be wide enough for the driver to stand behind the truck as usual. Sometimes, they will have to stand to the side, carefully manoeuvring the truck from an awkward position to line it up with the pallet.

If there’s a platform on the pedestrian truck, the driver also has to spend time flipping it up and down. With a stand-in stacker, the driver is inside, and the back of the truck can come very close to the front of the opposite rack with no problems.

This dramatically cuts down the time needed to place or retrieve a pallet, boosting efficiency significantly.

Stability

For a truck with a fairly slim profile, you can rely on the stand-in stacker to keep steady when lifting heavy pallets to high heights. The four-point design of a truck like the Ergo A offers maximum stability, especially compared to a five-point design which uses spring-loaded wheels to deal with uneven surfaces. The four-point truck does require flat floors to operate to its full potential - but the extra stability is worth it.

Are you convinced about the benefits of stand-in stackers yet? You may not have considered them before, but it’s worth thinking about whether these features could improve the safety and efficiency of your daily materials handling tasks. If you want to know more about how a stand-in stacker could benefit your operation, click the blue button below to get in touch and we’ll get back to you as soon as possible.

Comment