Automated guided vehicle (AGV) technology has been used in materials handling for decades, but with more recent developments in technology it's becoming a more affordable and flexible solution than it used to be.

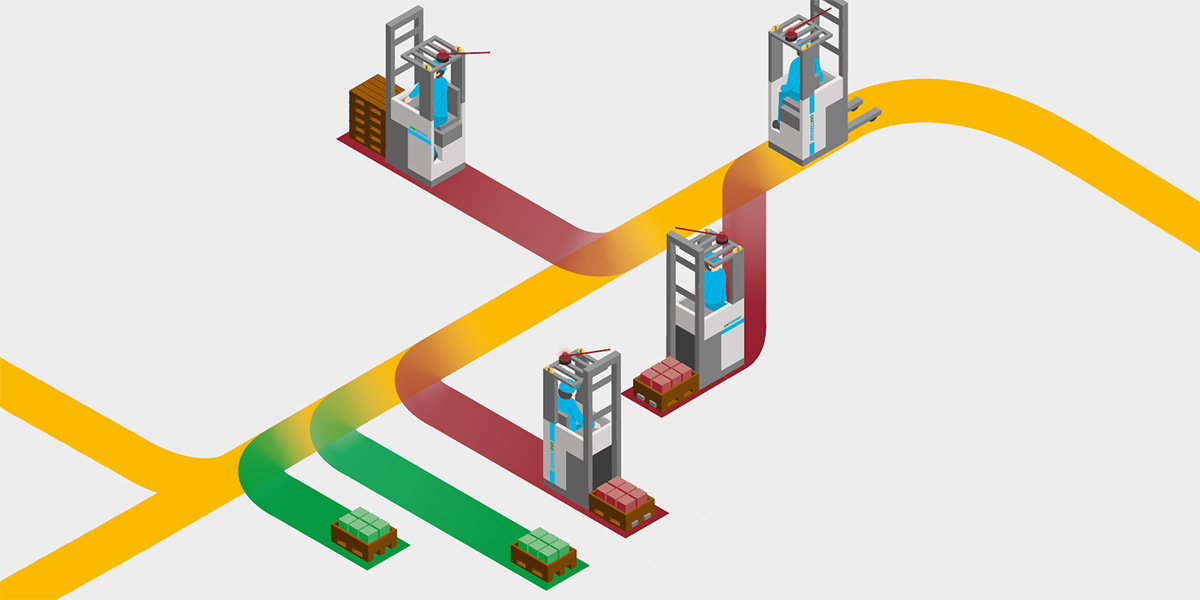

However, in some operations full automation may not be appropriate. This is especially true if the materials handling work that needs to be done is different from day to day, if it needs some level of human decision making or if order picking of many varied items makes up a big part of the work.