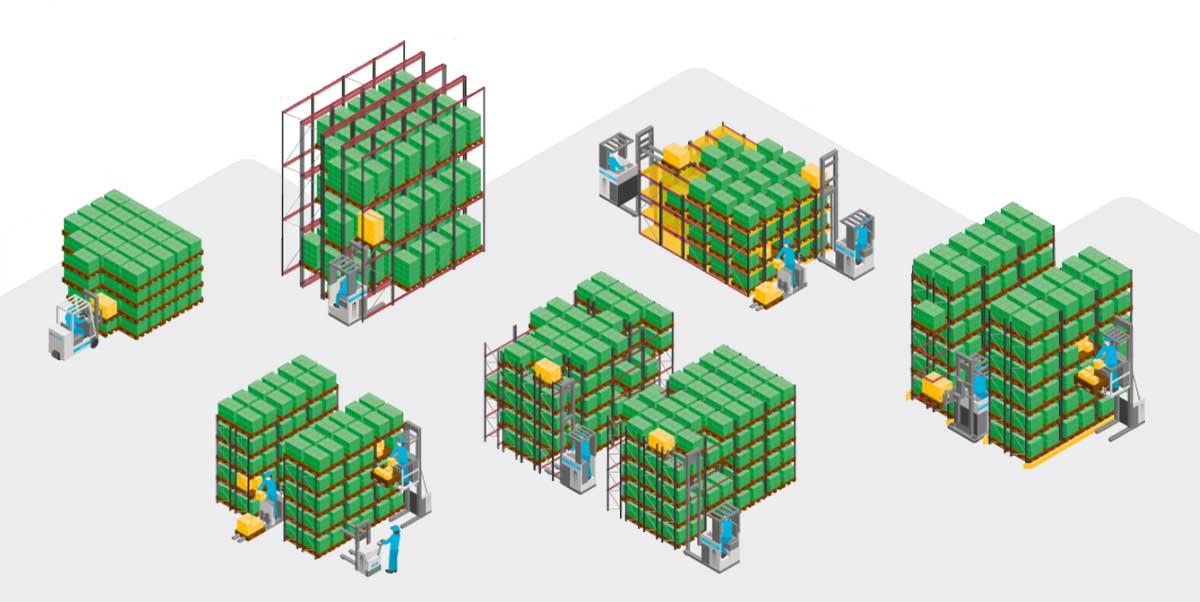

Shuttle racking certainly isn't the cheapest storage system available, but if you want to maximise the capacity of a warehouse, it's a fantastic option.

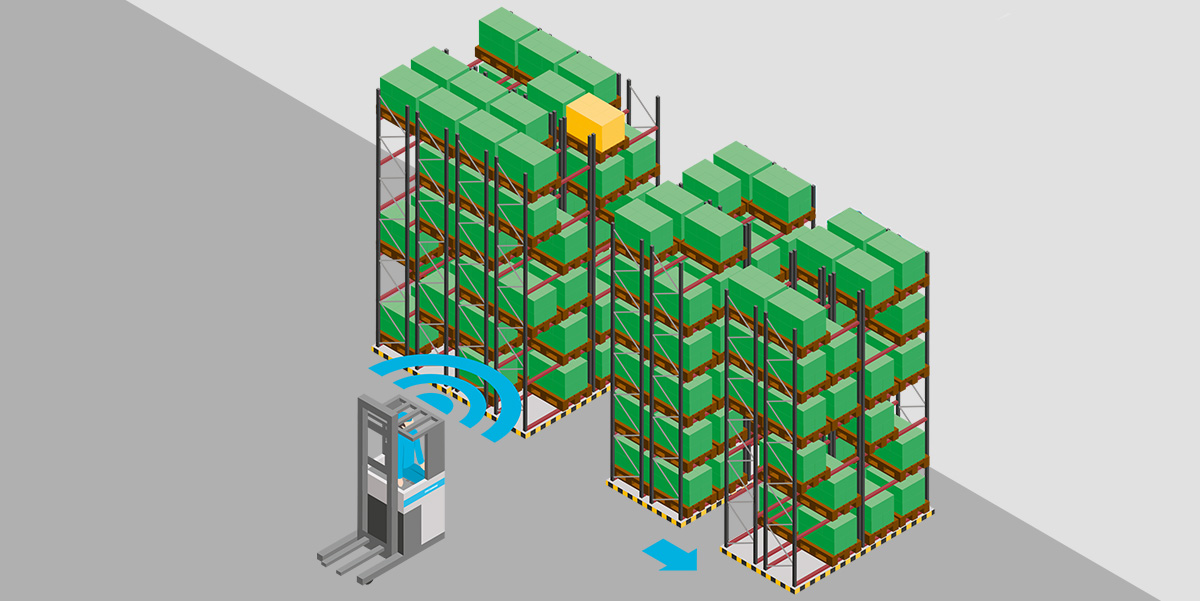

In shuttle racking systems, pallets are moved within the racks by a robotic shuttle, a kind of sled which runs on tracks just underneath the beams that the pallets sit on. An ordinary, manually-operated forklift places the shuttle into the rack at the desired height and pallet position, and the load to be put away is placed on the shuttle.