As we know, one small part of a logistics operation can have knock-on effects in other areas - and by improving and optimising these areas, you can increase productivity and efficiency with relatively little effort.

The warehouse building: Five small things that can make a big difference

Loading and unloading goods: How to get it right in your warehouse

Moving goods around inside your warehouse and storing them in a rational way is a major challenge - but the process of actually getting the goods inside in the first place is also filled with potential problems. High costs, queueing and inefficiency can all arise when you're not unloading optimally. That's why making the process as smooth and quick as possible can have a positive 'knock-on' effect on the rest of your operation.

How to know when to retire or replace your forklift truck

No matter the quality of your forklift truck, after a few years of service in a busy and fast-moving warehouse, it’s not going to have quite the same performance as it did when it was brand new.

Productivity and efficiency in the warehouse can really suffer once a forklift becomes too unreliable, and the time will always come when you need to replace it.But how do you know how long a forklift should last? And are there any alternatives to replacement? The diagram above should give a clear description of what your options are, and when you should consider them.

Giveaway: Keep forklift safety basics on your mind with our free poster

Forklift safety is vital in the modern warehouse. If you want to keep efficiency high and staff happy, making sure that forklift drivers know the rules is essential. Paying attention to the regulations also reduces the risk of breaking the law, too.

Accidents can harm your bottom line and damage your company's reputation - so keeping the best practice at the top of your mind is important.

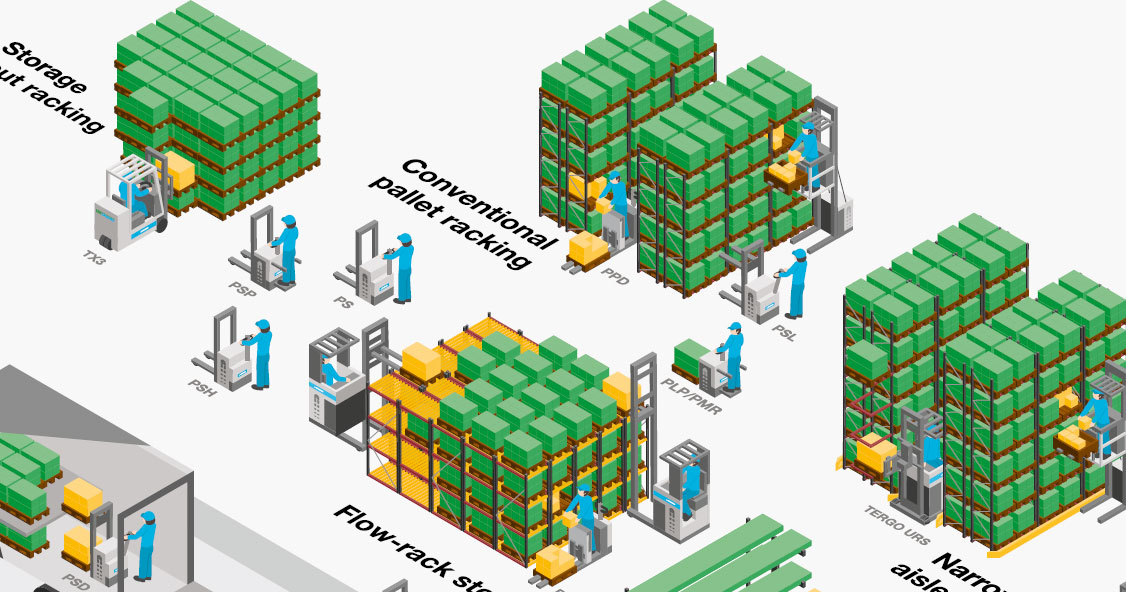

Guide: The best warehouse storage solutions for your operation

Double-deep storage, drive-in racking, narrow aisles - the list of warehouse storage options is extensive, and continues to grow as the demands on the material handling and logistics industries grow and change.

Each system has its benefits and drawbacks, and certain methods of storage are more suited to some operations than others. There's a wealth of detailed information out there about the best warehouse racking and different storage systems, but to make things easier, we've collected the basics in a simple PDF guide.

Six ergonomic features you should look for on your next forklift truck

It’s possible to spend large amounts of time and money trying to reduce logistics costs by making small changes around the warehouse - but when it comes to the total cost of owning your truck over its lifetime, the driver is often the biggest factor, and can sometimes make up 70% of the total cost.

Warehouse storage systems: Three important things to remember

The range of warehouse storage options available today is extensive, and the best choice of storage system for different kinds of items can depend on a large number of different factors.

How warehouse ergonomics and safety can boost your bottom line

Keeping warehouse staff happy, satisfied and motivated is a challenge which warehouse managers face every day. A big part of this challenge is safety - protecting staff from injury is one of the most basic requirements, and the industry has improved greatly in this area in the last few decades.

However, staying compliant with the law and keeping drivers happy aren't the only advantages - devoting resources to maintaining a safe and ergonomic warehouse environment can also bring financial benefits.

IFRS 16 Leases, and what it means for the material handling industry

On 1 January 2019, IFRS 16 Leases will come into effect, and it's going to have a big impact on the material handling industry.

How to choose the perfect forklift truck for your warehouse

The range of trucks currently available is huge, and new equipment and innovations are hitting the market all the time.

Even for experienced material handling professionals, weighting up all the advantages and disadvantages of each truck can be difficult. Forklifts that fit in perfectly in one warehouse may be unsuitable for another, and some trucks can be useful in very different stages of the handling process.

To make things simpler, we've explained it all.