There's many ways that the carbon footprint of a materials handling operation can be reduced. Using electric trucks instead of IC trucks brings down emissions, for example, and energy can be saved by choosing more eco-friendly heating and lighting systems.

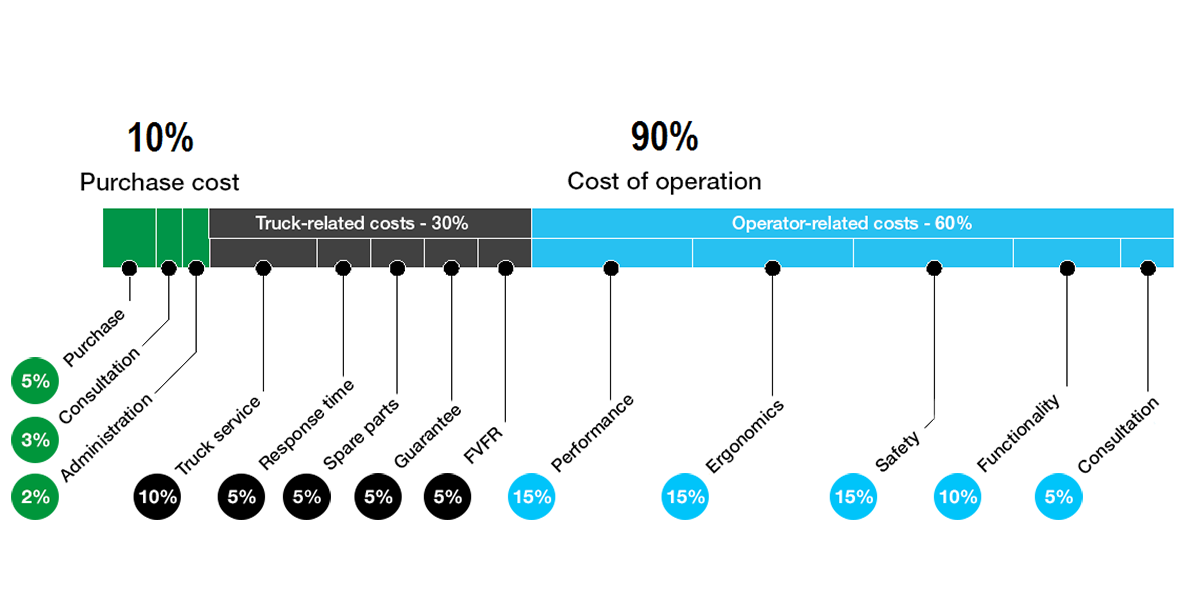

However, if you want to reduce the carbon footprint of your company's forklift service operation, then choosing a service partner with a high first visit fix rate (FVFR) is a great solution.