The warehouse floor certainly isn't the most exciting part of a materials handling operation, but it's the part on which everything else is built — and flooring-related problems can be a big safety hazard.

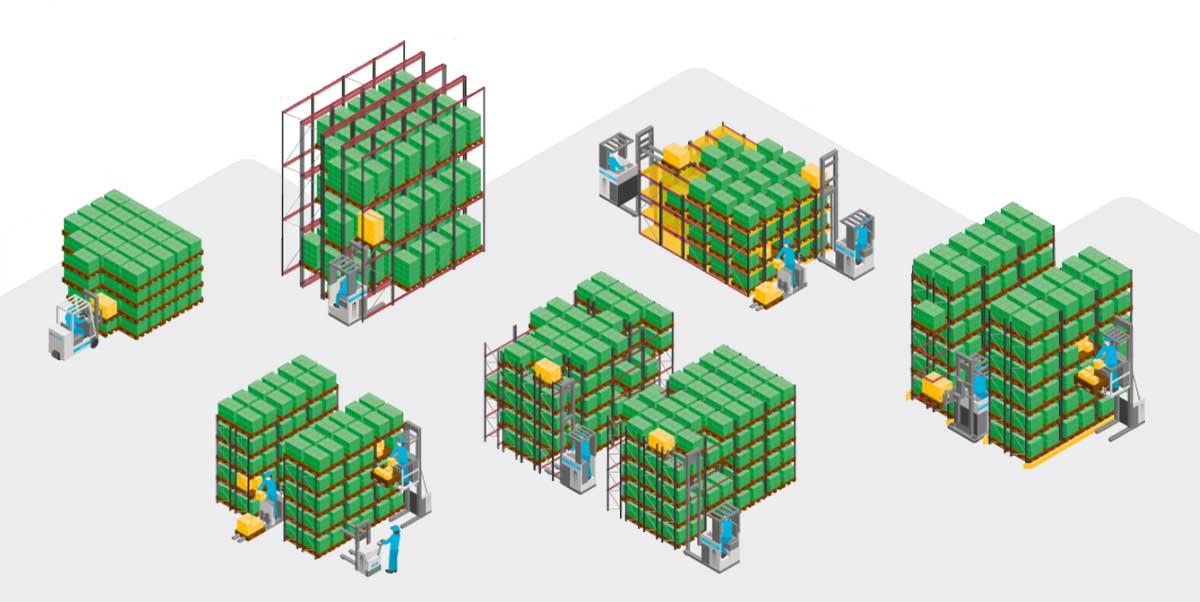

At the very least, the warehouse floor must be able to bear the load of the racking and goods and the truck traffic. When you consider that a single piece of racking may be placing many tons of pressure on a small point on the floor, the importance of quality becomes clear.

In most warehouses, concrete flooring will be standard. It’s capable of bearing at least twice as much weight as asphalt, and can be much smoother and flatter, which is important - even small bumps and hollows in the floor can affect truck driving, and even cause accidents in some circumstances.

Depending on the height of the racks, the neccessary flatness can be different. A normal floor, which may vary in height by 5mm across a length of two metres, would generally be good enough for material handling at heights up to three metres. However, for high bay warehouses, that tolerance may drop to only 1.5mm or less. When heavy loads are moved at such high heights, even the slightest variations may be hazardous, so careful construction of the concrete flooring is essential.